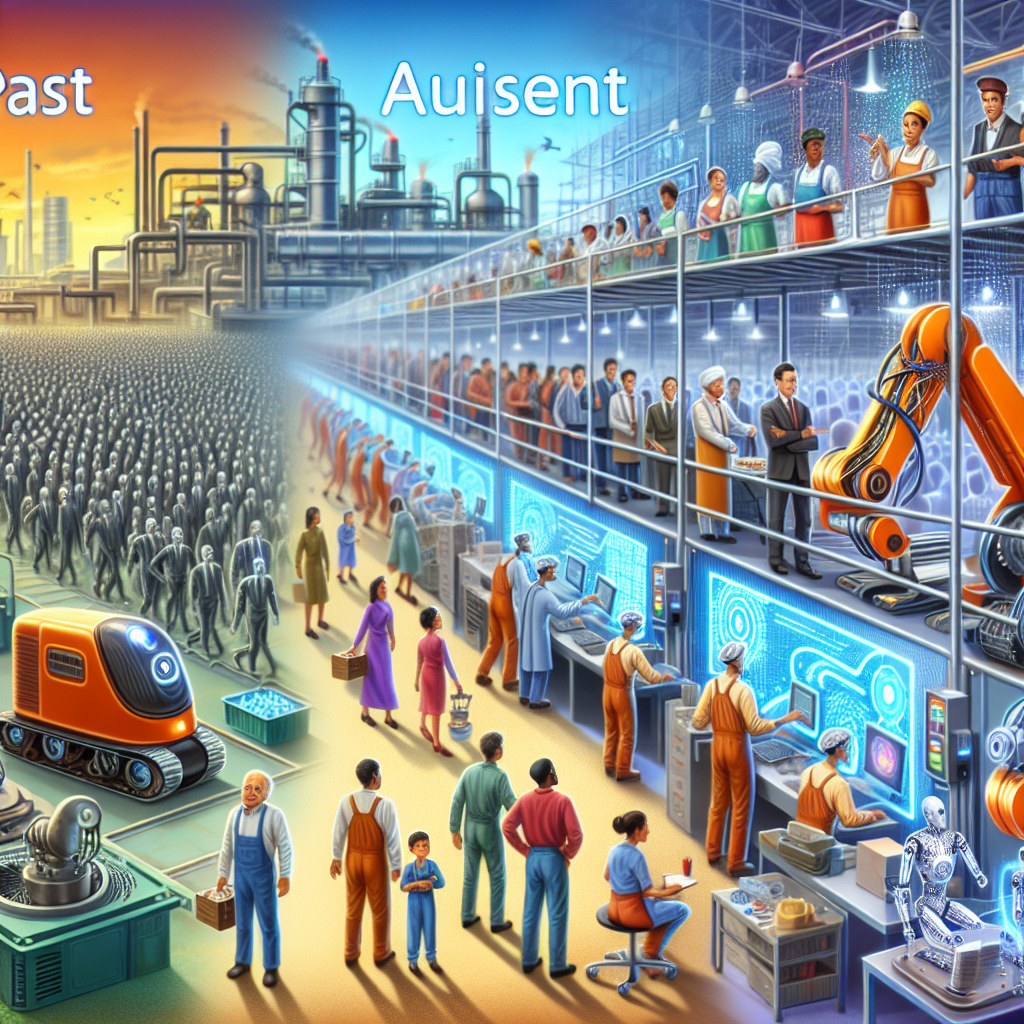

In the realm of advanced technology, Artificial Intelligence (AI) has emerged as a transformative force with the potential to revolutionize various industries. Manufacturing, in particular, stands to benefit immensely from the evolution of AI, as it offers unprecedented opportunities to optimize processes, increase efficiency, and unlock new possibilities for innovation.

AI, a branch of computer science that simulates human intelligence processes using machines, has come a long way since its inception. Initially, AI was limited to rule-based systems and simple algorithms. However, with the advent of machine learning and deep learning algorithms, AI has evolved into a sophisticated tool capable of learning from data, recognizing patterns, and making decisions autonomously.

The integration of AI in manufacturing has led to the development of smart factories, where machines communicate with each other and make real-time decisions to optimize production processes. For instance, AI-powered predictive maintenance can anticipate equipment failures before they occur, minimizing downtime and reducing maintenance costs. Similarly, AI-driven quality control systems can detect defects with high precision, ensuring that only the highest quality products reach the market.

Furthermore, AI enables manufacturers to enhance product customization and personalization, thereby meeting the growing demands of consumers for tailor-made products. By analyzing customer data and preferences, AI can recommend personalized products, streamline production processes, and optimize supply chain management.

One of the key advantages of AI in manufacturing is its ability to enhance productivity and efficiency. By automating repetitive tasks and optimizing workflow processes, AI can streamline operations, reduce costs, and increase output. This not only boosts profitability but also enables manufacturers to focus on value-added tasks that require human intervention, such as innovation and design.

Moreover, AI opens up new avenues for research and development in manufacturing. For instance, AI-powered simulation models can test and optimize product designs in a virtual environment, reducing the need for physical prototypes and speeding up the development cycle. Additionally, AI can uncover hidden patterns in data that human analysts may overlook, leading to breakthroughs in materials science, process optimization, and quality management.

Despite the numerous benefits of AI in manufacturing, there are challenges that must be addressed to realize its full potential. Chief among these is the need for skilled workers who can understand and leverage AI technologies effectively. Manufacturers must invest in training programs to upskill their workforce and create a culture that embraces AI as a tool for innovation rather than a threat to job security.

In conclusion, the evolution of AI represents a paradigm shift in the manufacturing industry, offering unprecedented opportunities for optimization, innovation, and growth. By harnessing the power of AI, manufacturers can transform their operations, drive efficiency, and unleash the future potential of their businesses. As AI continues to evolve, it is imperative for manufacturers to adapt, embrace change, and leverage technology to stay competitive in an increasingly digital world.